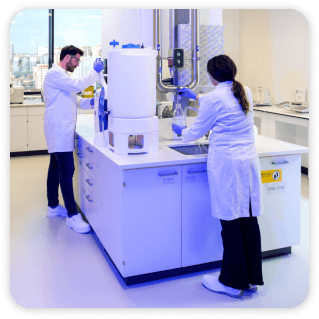

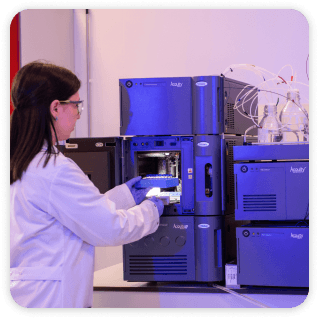

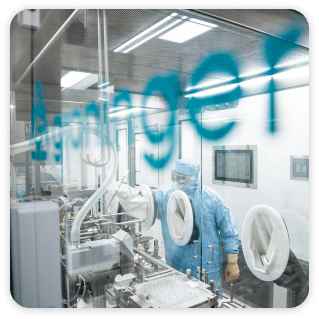

The water system established in Turgut Gebze Biopharmaceutical Manufacturing Facility to be used in biotechnological production and sterile filling lines, produces high quality pure water, pure steam and water for injection in accordance with international GMP standards. The water stored in the tanks is distributed to the microbiology laboratory, process sciences laboratory, quality control laboratory and production and sterile filling areas in line with the need through the automation system equipped with the latest technology. This automation system enables the control of the distribution system, monitoring of quality parameters and keeping records of data.